创新背景

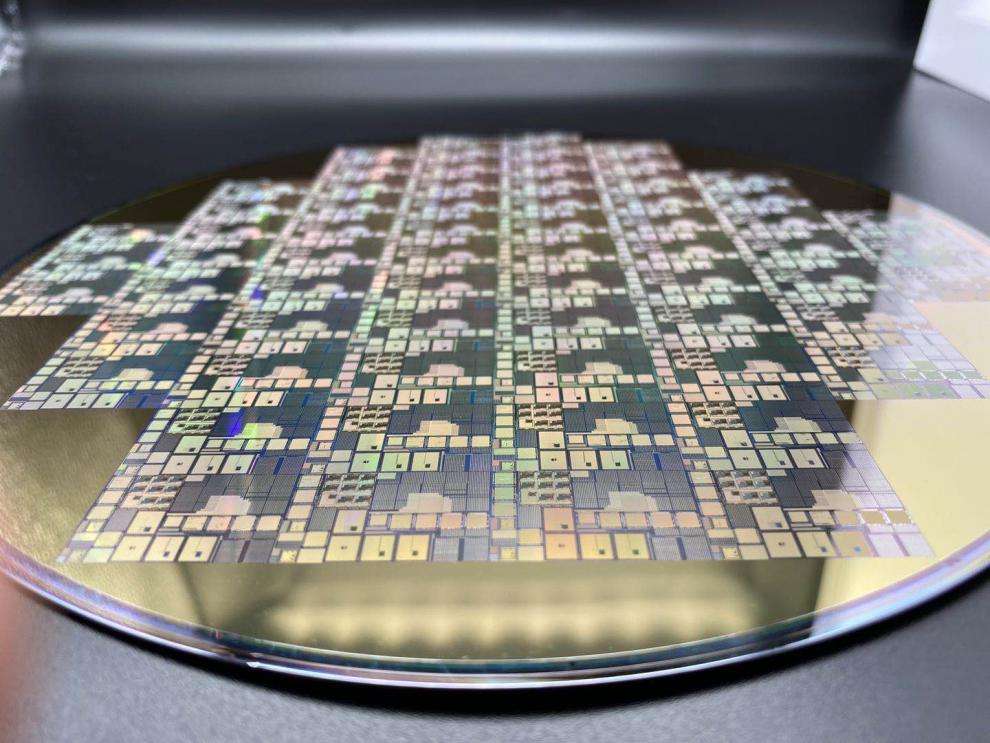

晶体管和其他纳米级器件通常是由上而下制造的——材料被蚀刻掉以达到所需的纳米结构排列。但是,制造最小的纳米结构需要昂贵的设备,而且很难大规模实现所需的分辨率,尽管它可以实现最高的性能和新功能。

组装纳米级设备的更精确的方法是自下而上。在一种方案中,工程师使用化学方法在溶液中“培养”纳米颗粒,将溶液滴到模板上,排列纳米颗粒,然后将它们转移到一个表面上。然而,这种技术也包含着严峻的挑战。首先,成千上万的纳米粒子必须高效地排列在模板上。将它们转移到一个表面通常需要化学胶水、大压力或高温,这可能会损坏表面和由此产生的设备。

创新过程

麻省理工学院的研究人员开发了一种技术,可以精确地控制纳米粒子在材料上的排列和位置,比如用于计算机芯片的硅,在某种程度上不会损坏或污染材料的表面。

研究人员利用纳米尺度上存在的强大力量,有效地将粒子排列成所需的模式,然后在没有任何化学物质或高压的情况下,在较低的温度下,将它们转移到表面上。由于表面材料保持原始状态,这些纳米级结构可以集成到电子和光学器件的组件中,即使是微小的缺陷也会影响性能。

新方法允许研究人员通过力的工程,将极小的纳米颗粒利用确定的单粒子分辨率安排在不同的表面上,创建具有非常独特的特性的纳米级积木库。通过将这些构建模块与其他纳米结构和材料集成,可以实现具有独特功能的设备。

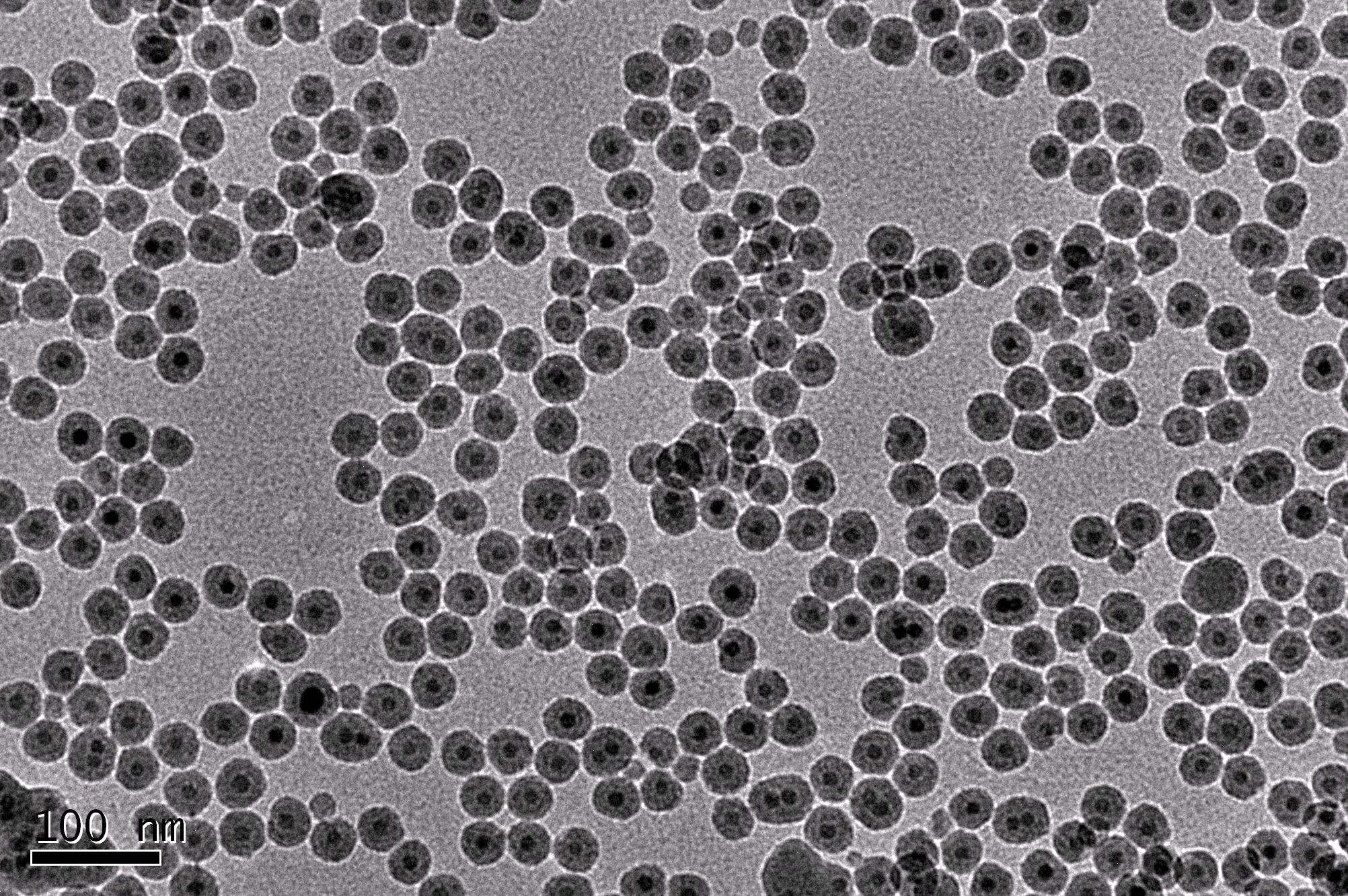

为了开始他们的制造方法,即纳米颗粒接触打印,研究人员使用化学方法在溶液中制造出具有特定大小和形状的纳米颗粒。在肉眼看来,这看起来像一小瓶彩色液体,但用电子显微镜放大会发现数百万个立方体,每个只有50纳米大小。(一根头发大约8万纳米宽。)

然后,研究人员制作了一个柔性表面的模板,上面覆盖着纳米颗粒大小的导流器或陷阱,这些导流器按他们想要的纳米颗粒的形状排列。在模板中加入一滴纳米粒子溶液后,他们使用两个纳米级的力将粒子移动到正确的位置。然后纳米颗粒被转移到任意表面上。

在纳米尺度上,不同的力起主导作用(就像重力在宏观尺度上起主导作用一样)。当纳米颗粒处于液体中时,毛细管力占主导地位,而在纳米颗粒与固体表面接触时,范德华力占主导地位。当研究人员加入一滴液体并拖动它穿过模板时,毛细管力将纳米颗粒移动到所需的陷阱中,将它们精确地放置在正确的位置。一旦液体干了,范德华力将这些纳米颗粒固定在原位。

研究人员将模板导轨设计成合适的尺寸和形状,并以精确正确的排列方式,使力共同作用来排列粒子。然后,纳米颗粒被打印到表面上,不需要任何溶剂、表面处理或高温。这保持了表面的原始和性能的完整性,同时允许超过95%的收率。为了促进这种转移,需要设计表面力,使范德华力足够强,以持续促进粒子从模板中释放,并在接触时附着在接收表面上。

该团队利用这种技术将纳米颗粒排列成任意形状,比如字母表中的字母,然后将它们以非常高的位置精度转移到硅中。该方法也适用于具有其他形状的纳米颗粒,如球体和不同的材料类型。它可以有效地将纳米颗粒转移到不同的表面,比如金,甚至是下一代电气和光学结构和设备的柔性基底。

创新关键点

研究人员使用化学方法在溶液中制造出具有特定大小和形状的纳米颗粒,并且制作了一个柔性表面的模板,上面覆盖着纳米颗粒大小的导流器或陷阱,这些导流器按他们想要的纳米颗粒的形状排列。

创新价值

该新型技术将化学和定向组装过程与传统制造技术相结合,能够有效地形成与纳米颗粒集成的高分辨率纳米级特征,用于传感器、激光器和led等设备,这可以提高它们的性能。

New technologies have been developed to precisely align nanoparticles on the surface of materials

MIT researchers have developed a technique that can precisely control the arrangement and position of nanoparticles on a material, such as silicon used in computer chips, in a way that doesn't damage or contaminate the surface.

The researchers took advantage of the powerful forces present at the nanoscale to efficiently arrange the particles into the desired pattern and then transfer them to the surface at lower temperatures, without any chemicals or high pressure. Since surface materials remain pristine, these nanoscale structures can be integrated into components of electronic and optical devices, where even minor defects can affect performance.

The new approach allows researchers to arrange extremely small nanoparticles on different surfaces using a determined single-particle resolution through force engineering, creating nanoscale building blocks libraries with very unique properties. By integrating these building blocks with other nanostructures and materials, devices with unique functions can be realized.

To get started with their manufacturing method, known as nanoparticle contact printing, the researchers used a chemical method to create nanoparticles with a specific size and shape in solution. To the naked eye, this may look like a vial of colored liquid, but electron microscopy reveals millions of cubes, each just 50 nanometers in size. (A human hair is about 80,000 nanometers wide.)

The researchers then made a template of a flexible surface covered with nanoparticle sized guides or traps that were arranged in the shape they wanted the nanoparticles to be. After adding a drop of nanoparticle solution to the template, they used a force of two nanometers to move the particles into the correct position. The nanoparticles are then transferred onto any surface.

At the nanoscale, different forces dominate (just as gravity dominates at the macroscopic scale). Capillary forces dominate when the nanoparticle is in liquid, while van der Waals forces dominate when the nanoparticle is in contact with a solid surface. When the researchers added a drop of liquid and dragged it through the template, capillary forces moved the nanoparticles into the desired trap, placing them precisely in the right place. Once the liquid dries, van der Waals forces hold the nanoparticles in place.

The researchers designed the template rails to be the right size and shape, and arranged in precisely the right way, so that forces work together to align the particles. The nanoparticles are then printed onto the surface without any solvents, surface treatments or high temperatures. This maintains the surface's original and performance integrity while allowing for more than 95% yield. To facilitate this transfer, surface forces need to be designed such that van der Waals forces are strong enough to continuously promote particle release from the template and attachment to the receiving surface upon contact.

The team used the technique to arrange nanoparticles into arbitrary shapes, such as letters of the alphabet, and then transfer them into silicon with very high positional accuracy. The method is also applicable to nanoparticles with other shapes, such as spheres, and different material types. It can efficiently transfer nanoparticles to different surfaces, such as gold, or even flexible substrates for next-generation electrical and optical structures and devices.

智能推荐

生物医学创新思维 | 新型碳基纳米材料作为药物载体材料创新应用于生物医学领域

2022-07-27中国科学院理化技术研究所光电功能界面材料实验室自2010年开始研究基于纳米金刚石的癌症治疗体系,发现在酸性细胞环境内,纳米金刚石-顺铂体系可实现顺铂药物的缓释效果,能显著抑制HeLa细胞的增殖(Small 2010, 6, 1514-1519)。后续研究发现了高压高温法制备的纳米金刚石对HepG2细胞的迁移抑制效果(Physica Status Solidi A 2016, 213, 2131-2137)。

涉及学科涉及领域研究方向药学创新思维 | 基于DNA纳米的药物开发新技术可减少制药时间

2022-06-29由哥本哈根大学的黑扎吉斯团队和南丹麦大学斯蒂芬·沃格尔副教授合作完成的,被命名为“基于DNA介导融合的单粒子组合脂质纳米容器融合”(SPARCLD)的研究解决方案,可在比针头还小的区域内,合成和分析超过4万种不同的分子,有望大幅减少制药公司的材料、能源和经济成本和时间。该方法通过使用类似肥皂泡的纳米容器,借助DNA纳米技术,可在容器中混合多种成分。

涉及学科涉及领域研究方向