创新背景

使用现有的固态电解质,当增加材料的机械强度时,则会牺牲很多导电性。如果想要更高的导电性,材料就没有那么坚固。

创新过程

新南威尔士大学的工程师开发了一种工艺,可以将固态聚合物电解质打印成任何需要的形状,用于储能。

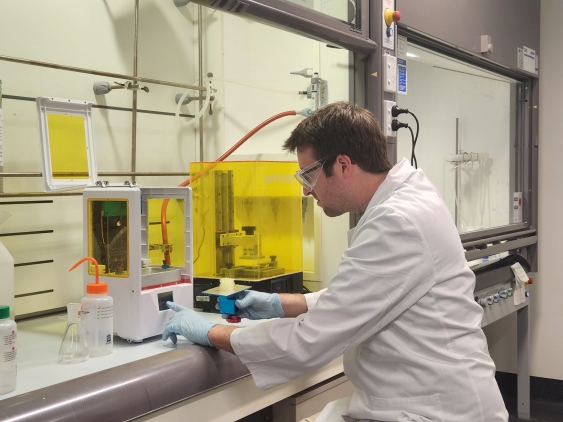

由Cyrille Boyer教授领导的化学工程学院的研究团队,包括Nathaniel Corrigan博士和Kenny Lee说,这种材料的3D打印过程在未来的医疗设备中特别有用,小型、复杂的设计为能量存储提供了许多好处。

固体电解质是固态电池的关键部件,尽管传统上由于离子导电性低或机械性能差,它们的性能很差。

然而,在《先进材料》杂志上发表的一篇论文中,新南威尔士大学的研究团队报告称,他们的3D打印固体聚合物电解质(SPE)具有高导电性和强大的强度。

这意味着固态电解质有可能被用作设备的实际结构,创造了一系列可想象的设计机会,特别是对未来的医疗产品。

之前没有人3D打印过固体聚合物电解质。传统上,它们是用模具制造的,但之前的工艺无法控制材料的强度,或将其形成复杂的形状,使用现有的固态电解质,当增加材料的机械强度时,则会牺牲很多导电性。如果想要更高的导电性,材料就没有那么坚固。研究人员已经实现了两者的同时结合,这可以3D打印成复杂的几何图形。

这种聚合物电解质具有成为承重储能材料的潜力。由于它的强度,它可以用作小型电子产品的实际结构,或航空航天应用,或小型个人医疗设备,因3D打印过程可以非常复杂和精确。

人们可以用这种新型系统创造非常微小的结构。因此,它在纳米技术和任何需要设计微型储能的地方都有奇妙的应用。

增加循环稳定

尽管新南威尔士大学研究小组开发的固体聚合物电解质被认为是一种高性能材料,但研究人员说,它可以使用廉价的商用3D打印机制造,而不是复杂的工程设备。

本文所描述的固相萃取是由嵌入刚性交联聚合物基体中的纳米级离子传导通道组成的。它的生产过程称为聚合诱导微相分离(PIMS)。

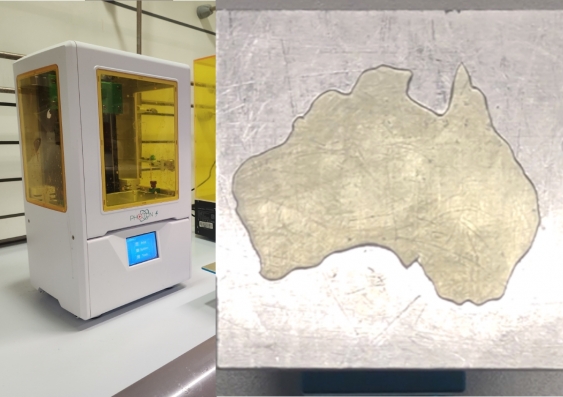

为了展示这种材料的多功能性,研究人员3D打印了一幅复杂的澳大利亚地图,然后将其作为一种能量存储设备进行测试。

在储能设备中,SPE的另一个好处是它增加了循环稳定性——也就是充电和放电循环的次数,直到容量减少到一定数量,在论文中,研究人员展示了这种材料非常稳定,有能力在数千个循环中充放电。3000次循环后,只有大约10%的下降。

研究人员表示,与其他传统制造形式相比,3D打印还减少了浪费,降低了成本,因为同一台机器可以用来生产各种不同形状的材料。在未来,产品设计师可以利用他们的SPE来创造具有更高能量储存密度的产品。

想象一下,一个主要由这种材料制成的耳塞,它也可以充当电池。存储密度将大大提高,因此电力将持续更长时间。

创新关键点

之前没有人3D打印过固体聚合物电解质。传统上,它们是用模具制造的,但之前的工艺无法控制材料的强度,或将其形成复杂的形状,使用现有的固态电解质,当增加材料的机械强度时,则会牺牲很多导电性。如果想要更高的导电性,材料就没有那么坚固。研究人员已经实现了两者的同时结合,这可以3D打印成复杂的几何图形。

创新价值

固态电解质在未来有可能被用作设备的实际结构,特别是对未来的医疗产品。

这种聚合物电解质具有成为承重储能材料的潜力。由于它的强度,它可以用作小型电子产品的实际结构,或航空航天应用,或小型个人医疗设备,因3D打印过程可以非常复杂和精确。

创新主体

新南威尔士大学(The University of New South Wales),简称UNSW,创立于1949年,主校区坐落于南半球金融、贸易与旅游中心——澳大利亚新南威尔士州首府悉尼,是一所公立研究型大学,为澳大利亚八校联盟、环太平洋大学联盟、国际科技大学联盟、Universitas 21和英联邦大学协会成员。

A solid polymer is fused with an electrolyte and can be customized using 3D printing technology

Engineers at the University of New South Wales have developed a process that can print solid polymer electrolytes into any desired shape for energy storage.

The research team from the School of Chemical Engineering, led by Professor Cyrille Boyer and including Dr Nathaniel Corrigan and Kenny Lee, said the 3D printing process of this material could be particularly useful in future medical devices, where the small, complex design offers many benefits for energy storage.

Solid electrolytes are key components of solid-state batteries, although traditionally they perform poorly due to low ionic conductivity or poor mechanical properties.

However, in a paper published in the journal Advanced Materials, the University of New South Wales research team reports that their 3D printed solid polymer electrolytes (SPEs) are highly conductive and strong.

This means that solid electrolytes have the potential to be used as the actual structure of devices, creating a range of conceivable design opportunities, especially for future medical products.

No one had 3D-printed solid polymer electrolytes before. Traditionally, they are made with molds, but previous processes were unable to control the strength of the material, or shape it into complex shapes, using existing solid electrolytes that sacrifice a lot of electrical conductivity when increasing the mechanical strength of the material. If you want higher conductivity, the material is not as strong. Researchers have been able to combine both simultaneously, which can be 3D printed into complex geometry.

This polymer electrolyte has the potential to be a load-bearing energy storage material. Because of its strength, it can be used as a practical structure for small electronic products, or aerospace applications, or small personal medical devices, because the 3D printing process can be very complex and precise.

This new system allows people to create very small structures. So it has fantastic applications in nanotechnology and anywhere you need to design miniature energy storage.

Increased cyclic stability

Although the solid polymer electrolyte developed by the UNSW team is considered a high-performance material, the researchers say it can be made using cheap commercial 3D printers rather than complex engineering equipment.

The SPE described here consists of nanoscale ion conduction channels embedded in a rigid cross-linked polymer matrix. Its production process is called polymer-induced microphase separation (PIMS).

To demonstrate the versatility of the material, the researchers 3D-printed a complex map of Australia and then tested it as an energy storage device.

In energy storage devices, another benefit of SPE is that it increases cycle stability -- that is, the number of charging and discharging cycles until the capacity is reduced to a certain number. In the paper, the researchers showed that the material is very stable and has the ability to charge and discharge over thousands of cycles. After 3,000 cycles, there's only about a 10% drop.

The researchers say 3D printing also reduces waste and costs compared to other traditional forms of manufacturing, because the same machine can be used to produce a variety of materials with different shapes. In the future, product designers can leverage their SPEs to create products with higher energy storage densities.

Imagine an earplug made mostly of this material, which also acts as a battery. Storage density will be much higher, so power will last longer.

智能推荐

使用硫化学气相沉积制备超高折射率的聚合物

2022-08-05通过一步法气相沉积工艺提高折射聚合物薄膜的高透明度。

涉及学科涉及领域研究方向创新使用木质涂料降低医院器具表面的微生物

2022-08-02将树脂和树皮与医院使用的抗菌材料进行对比,考虑木质涂料的可用性。

涉及学科涉及领域研究方向利用高性能水凝胶驱动材料模拟肌肉结构和功能

2022-07-28受肌肉结构的启发,宾夕法尼亚州立大学的研究人员研创出一种纤维驱动器的新设计。它模拟了肌肉纤维的结构,并在能效、驱动应变和机械性能等多个方面比其他现有驱动器更优越。这一结果发表在《自然·纳米技术》(Nature Nanotechnology)杂志上。

涉及学科涉及领域研究方向新材料 | 原子级超薄材料有望提高光电技术使用效率

2022-06-29采用原子结构排列创造超薄晶格,改进半导体芯片在光电技术中的使用效率。

涉及学科涉及领域研究方向