创新背景

oled首次用于平板电视是在20年前。该技术的优点之一是它们可以用于柔性、可弯曲的表面,而且它们可以由液体溶剂制成。这意味着它们是可打印的,为定制新的OLED设计提供了一种廉价的方式。

创新过程

该技术使用有机发光二极管(oled),其应用方式与水转移纹身相同。也就是说,有机发光二极管是在临时的纹身纸上制作的,然后通过压在纹身纸上并用水轻拍转移到一个新的表面上。

研究人员在《先进电子材料》(Advanced Electronic Materials)杂志上发表的一篇新论文中描述了这一过程,称它可以与其他纹身电子设备相结合,比如当运动员脱水时,或当我们需要远离太阳以避免晒伤时,它就会发光。oled可以被纹在包装或水果上,以表明产品已经过期或即将不能食用,或者以发光纹身的形式用于时尚。首次展示的可纹身oled可以大规模制造,成本非常低。未来的挑战包括尽可能封装oled,以防止它们与空气接触后快速降解,以及将设备与电池或超级电容集成。

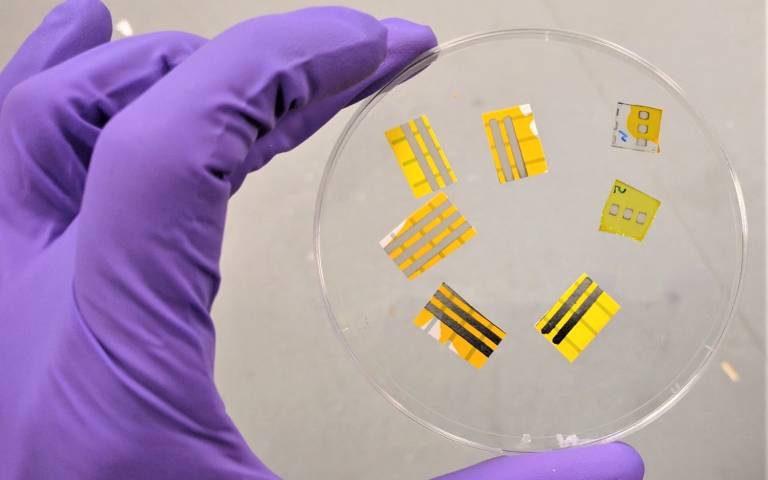

研究人员开发的OLED设备总共有2.3微米厚(不到一毫米的400分之一),大约是一个红细胞长度的三分之一。它由电极之间的电致发光聚合物(一种施加电场时发光的聚合物)组成。在电极和商业纹身纸之间放置一层绝缘层。

这种发光聚合物有76纳米厚(一纳米是一毫米的百万分之一),它是用一种称为旋转涂层的技术制造的,在这种技术中,聚合物被应用到高速旋转的基板上,产生一个非常薄且均匀的层。

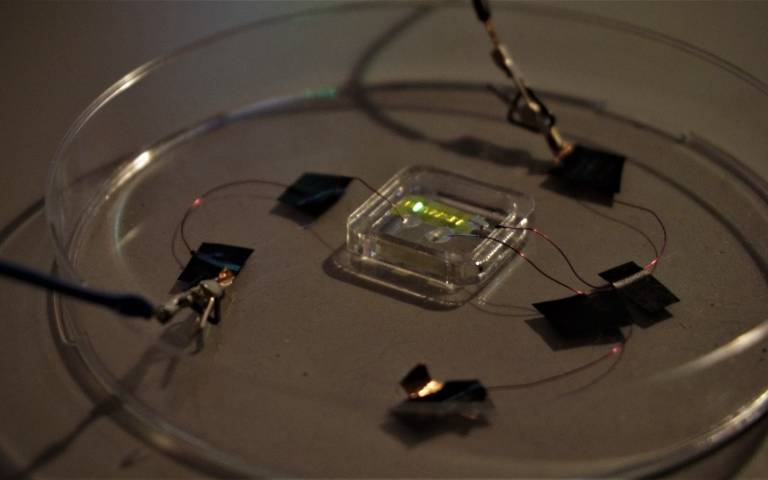

一旦他们建立了这项技术,研究团队就将可纹身的oled应用到一块玻璃、一个塑料瓶、一个橙子和纸包装上,这种oled会发出绿色的光。

资深作者、意大利理工学院研究员Virgilio Mattoli博士说:“纹身电子产品是一个快速发展的研究领域。在意大利理工学院,我们曾率先将电极纹在人的皮肤上,用于进行心电图等诊断测试。这项技术的优点是成本低,易于涂抹和使用,容易用肥皂和水清洗。

创新价值

它们可以与其他形式的纹身电子产品相结合,具有非常广泛的可能用途。这些可以用于时尚——例如,提供发光的纹身和发光的指甲。在运动中,它们可以与汗液传感器结合,发出脱水信号。在医疗保健领域,当病人的病情发生变化时,它们可以发光——或者,如果纹身以另一种方式进入皮肤,它们可能与针对癌细胞的光敏疗法结合在一起。

创新关键点

该技术使用有机发光二极管(oled),其应用方式与水转移纹身相同。也就是说,有机发光二极管是在临时的纹身纸上制作的,然后通过压在纹身纸上并用水轻拍转移到一个新的表面上。

创新主体

伦敦大学学院(University College London,简称:UCL ),1826年创立于英国伦敦,是一所公立研究型大学,为伦敦大学联盟的创校学院、罗素大学集团和欧洲研究型大学联盟创始成员,被誉为金三角名校和“G5超级精英大学”之一。

UCL是伦敦的第一所大学,以其多元的学科设置著称,于REF 2014 英国大学官方排名中,位列全英之冠,享有最多的科研经费。UCL的医学、解剖学和生理学、建筑学、教育学、考古学、计算机科学、计算金融学等学科排名均位居世界前列,与LSE并称为“英国现代经济学研究的双子星”;其人文学院颁发的奥威尔奖则是政治写作界的最高荣誉。

New 'Smart Tattoo' Designed with Light-Emitting Diodes

The technology uses organic light-emitting diodes (OLeds), which are applied in the same way as water-transfer tattoos. That is, the OLED is made on temporary tattoo paper and then transferred to a new surface by pressing on the tattoo paper and dabbing it with water.

The researchers, who describe the process in a new paper in the journal Advanced Electronic Materials, say it could be combined with other tattooed electronics, such as when athletes are dehydrated or when we need to stay out of the sun to avoid sunburn. Oleds can be tattooed on packaging or fruit to indicate that the product has expired or is about to become inedible, or used in fashion in the form of luminous tattoos. The tattooable OLeds shown for the first time can be manufactured on a large scale at very low cost. Future challenges include packaging OLEDPs as much as possible to prevent their rapid degradation upon contact with air, and integrating devices with batteries or ultracapacitors.

In total, the OLED devices developed by the researchers are 2.3 microns thick (less than 400th of a millimeter), about a third the length of a red blood cell. It consists of an electroluminescent polymer (a polymer that emits light when an electric field is applied) between electrodes. An insulating layer is placed between the electrodes and the commercial tattoo paper.

The light-emitting polymer is 76 nanometers thick (a nanometer is a millionth of a millimeter) and was made using a technique called rotary coating, in which the polymer is applied to a substrate that rotates at high speed to produce a very thin and uniform layer.

Once they built the technology, the team applied the tattooable OLED, which glows green, to a piece of glass, a plastic bottle, an orange and paper packaging.

Senior author Dr Virgilio Mattoli, a researcher at the Italian Institute of Technology, said: "Tattoo electronics are a rapidly growing area of research. At the Italian Institute of Technology, we were the first to tattoo electrodes on people's skin for diagnostic tests like electrocardiograms. The advantages of this technology are low cost, easy to apply and use, and easy to clean with soap and water.

Value innovation

They can be combined with other forms of tattooed electronics and have a very wide range of possible uses. These can be used in fashion - for example, providing glowing tattoos and glowing nails. During exercise, they can combine with sweat sensors to signal dehydration. In healthcare, they could glow when a patient's condition changes - or, if tattoos enter the skin in another way, they could be combined with light-sensitive therapies that target cancer cells.

智能推荐

激光+树脂 | 突破3D打印限制

2022-06-29综合利用激光、纳米材料和树脂实现3D打印无逐层结构支撑。

涉及学科涉及领域研究方向量子计算+机械工程 | 开发原型谐振器技术用于控制自旋量子比特

2022-09-22来自新南威尔士大学悉尼分校的量子工程师们扫除了量子计算机成为现实的一个主要障碍:他们发现了一种新技术。该技术将能够控制数百万个自旋量子位——硅量子处理器中的基本信息单位。

涉及学科涉及领域研究方向新材料 | 新型吸湿材料可减少防护服的热应激

2022-09-30创新利用蒸发冷却原理开发可控制防护服中微环境中的湿度水平的超吸湿性复合膜来,有效处理防护服的热应激。

涉及学科涉及领域研究方向反思可解释性方法,深入探索机器学习的原理

2022-07-23从可解释性方法的角度探索机器学习模型的工作准确性,拓展人工智能研究使用的注意事项。

涉及学科涉及领域研究方向